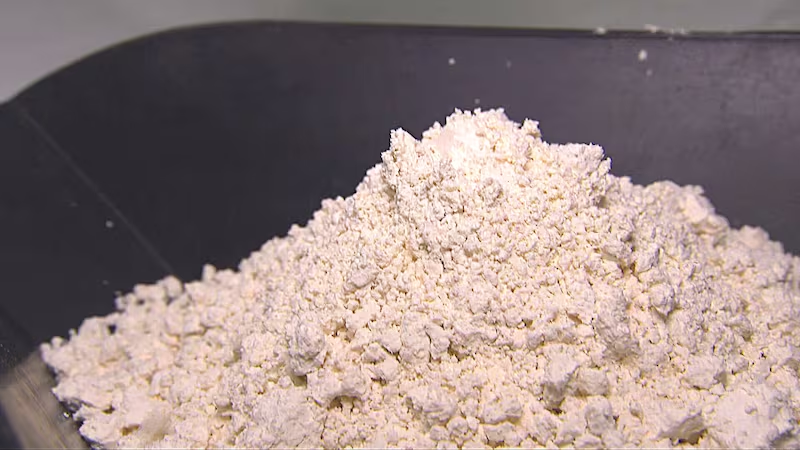

Canada grows millions of tonnes of soybeans each year, but not a single kilogram of a widely consumed food ingredient — soy protein isolate — is actually produced here.

Instead, the protein is extracted abroad, in places like the United States, then imported into Canada for use in products ranging from protein bars and infant formula to veggie burgers.

“It’s one of those ingredients where, when you start looking for it on the back of the package, you realize it’s all over the place,” says Graham Markham, chief development officer at New Protein International.

The Ontario-based company is aiming to change things by building Canada’s first large-scale facility in Canada that can process soybeans into soy protein here at home. And unlike other processors, they won’t use hexane, a neurotoxic byproduct of gasoline refining that’s long been used in conventional methods.

Instead, the company has developed a chemical-free process that uses mechanical pressure to extract the protein — a world-first, says Martin Vanderloo, a farmer who co-founded the company. He says it aligns with growing consumer demand for so-called clean-label, environmentally responsible ingredients.

He’s already built a demonstration plant and is now pushing ahead with plans for a full-scale facility in Sarnia, Ont., that would process 70,000 tonnes of soybeans annually and produce more than 17,000 tonnes of soy protein and food-grade byproducts. The project could employ more than 100 people and make Canada self-sufficient in soy protein production — with room to export.

“We’re ecstatic about it — we’ve been working hard to get this off the ground,” says Vanderloo.

It comes at a time when industries across Canada are looking to reduce their reliance on cross-border trade.

“It’s interesting that we’re finally starting to get noticed after some years working at this, that it’s going to be important for this country to be self-sustainable in food ingredient production, right here at home, right?”.

Farmer Bev Hill, who’s been growing soybeans in Ontario’s Huron County for decades, believes the new facility can’t come soon enough.

“Be delighted to see more of that,” he says. “Agriculture is one of the driving forces of the economy, and it certainly doesn’t get the attention and respect that most of us acknowledge it should.”

The timing may be right. Amid trade tensions, shifting supply chains and a growing awareness among Canadians about where their food comes from, domestic manufacturing is gaining renewed attention. Vanderloo says he’s received increased interest from industry and government, with more people asking when production can begin.

But the project hasn’t been easy to finance -- and Vanderloo is frustrated by what he sees as a lack of strong federal government support.

“The interest from government is more along the lines of EV batteries and critical minerals as opposed to agriculture, food and food production in this country.”

Construction is expected to begin in late summer or early fall and take three years. In the meantime, Vanderloo hopes to license the technology to others, potentially transforming how plant-based proteins are made worldwide.

“It’s been somewhat frustrating to get the financing in place -- support from government and others, but we’re getting there.”